The Carbolite CAF G5 is a furnace designed to test ash fusibility and, optionally, to determine the increasingly popular properties of biomass or solid recovered fuels.

The CAF G5’s automatic, continuous recording of digital images allows laboratory technicians to carry out other tasks while the test is in progress and then review the results later. The new CAF G5 dramatically enhances the quality of the recorded images and test results, increasing laboratory efficiency.

The maximum temperature of 1600 °C enables testing of both biomass and coal. An optional work tube integrated lighting system is also available when testing the low ‘initial deformation’ temperature of SRF or biomass samples.

The coal ash fusibility test furnace conforms to the Standards ISO 540:2008; ASTM D 1857 / D1857M – 04 (2010); DIN 51730:2007-09; DD CEN/TS 15370-1:2006 (biomass) and PD CEN/TR 15404:2010 (solid recovered fuels (SRF)).

Features

- 79mm internal diameter work tube.

- Integral SiC elements.

- 3508P1 automatic temperature programmer (20 segments) with multiple PID control.

- Software zoom function to enable an accurate post-test analysis of individual samples with improved resolution.

- One configurable grid is assigned to each test piece.

- Analysis software which can be used in fully automatic or manual modes.

- The temperature controller program is set up in the software.

- Space-saving embedded computer with Windows OS.

- Professional software runs future-proof firmware.

- Default software settings and individual analysis form for coal ash, biomass and SRF.

- Lightweight insulation allows quick cooling, permitting multiple tests to be completed during the day.

- Automated digital image capture of samples. The frequency of images recorded is set by customer preference, from every 1 °C increment to every 20 °C. The maximum interval for auto analysis is 5°C.

Supplied as standard

- Sample carrier x 1.

- Sample tiles x 100.

- Sample loading tool x 1.

- Test piece mould x 1 (coal ash).

- Test piece mould and hand press x 1 (biomass & SRF).

- External mounting proprietary CO alarm x 1.

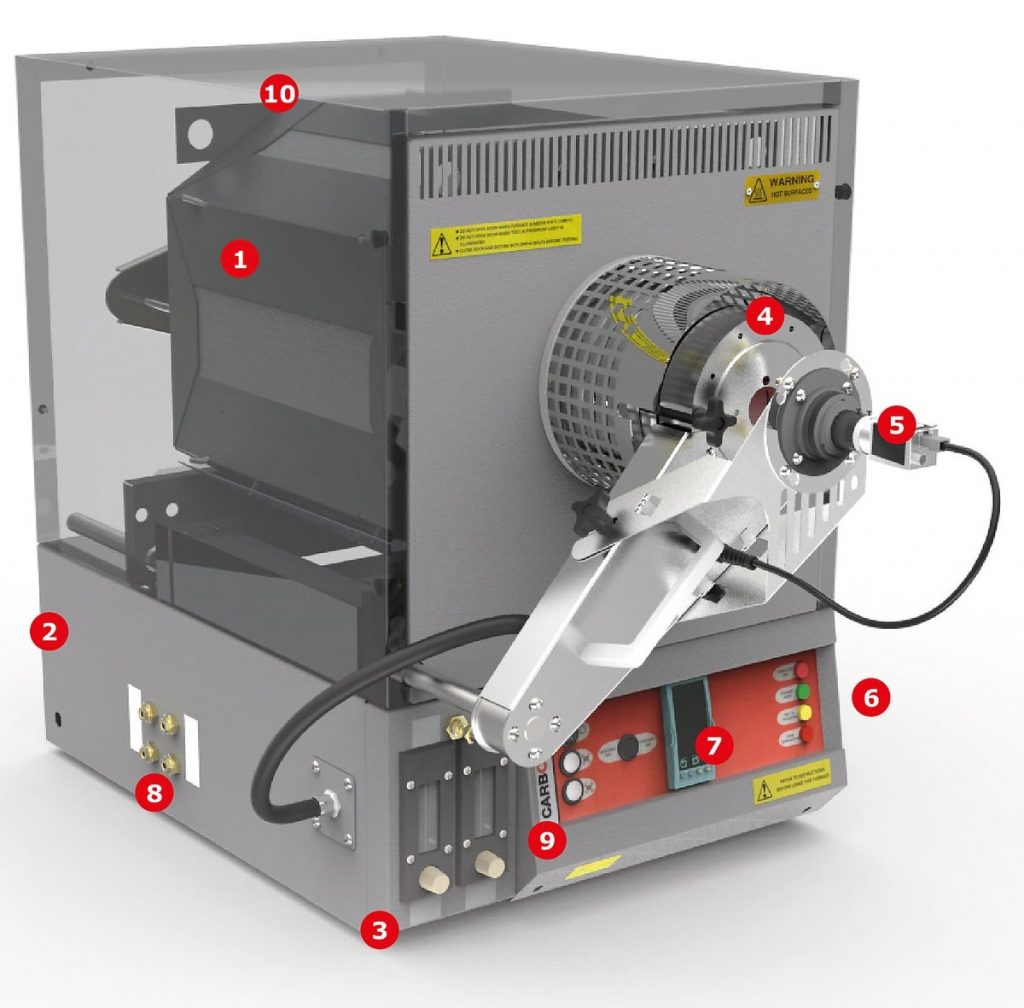

View inside

- 1600 °C tube furnace with integral SiC elements.

- External link to embedded PC & software.

- Flow meters for oxidising and reducing gas flow (dependent on the requirements of the standards).

- 79 mm inner-diameter work tube allows more than 6 samples.

- Digital camera for fast and accurate image recording.

- Gas-tight seal for efficient gas use & operator safety.

- Automatic temperature programmer with multiple PID control.

- Gas inlets for reducing, oxidising & purging gases.

- Oxidising or reducing gas selection switch.

- Work tube integrated light for use when testing the low ‘initial deformation’ temperature of biomass and SRF samples (optional).

Order Information

CAFG5-CO: CAF G5 1600°C CO/CO2, Ash fusibility testing tube furnace

CAFG5-H2: CAF G5 1600°C H2, Ash fusibility testing tube furnace

CAFG5-BIO: CAF G5 1600°C BIO, Ash fusibility testing tube furnace