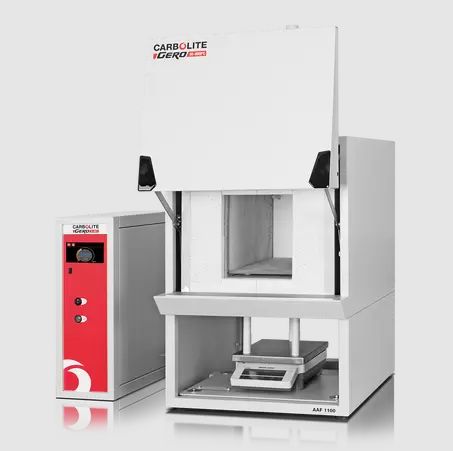

The AAF-BAL thermogravimetric analysis (TGA) furnace incorporates an integral balance. It can be used for loss-on-ignition applications where the sample’s weight change must be monitored during the heating process.

The AAF-BAL ashing furnace is fitted with an integral balance and can be used for loss-on-ignition (LOI) applications. The weight change of the sample is monitored during the heating process. This is required, for example, in determining the organic matter content in sediment, sludge, soil, and waste. Inorganic materials such as cement, lime, calcinated bauxite, and refractories can also be tested.

Features

- 3216cc controller with single ramp to setpoint and process timer.

- Protection of the elements from carbon build-up or corrosive atmosphere using silicon carbide tiles.

- Balance runs independently of the furnace control system.

- Maximum capacity of balance is 3 kg with a resolution of 0.01 (other capacities available).

Options

- Advanced version for EPC3008P10 to data-log both weight and temperature. It is also necessary to select the following options: EPC3008P10 instrument (which includes Ethernet communication). Data logging is done via iTools software, which must be purchased separately.

- The advanced version of the nanodac can data-log both weight and temperature. It is also necessary to select the following options: nanodac instrument. Data logging is done in the nanodac and can be downloaded into the ‘Review Lite’ software, which is included with the nanodac. Data can be archived onto a USB flash drive or via Ethernet to a networked server.

- Over-temperature protection (recommended to protect valuable contents and for unattended operation).

Order Information

| AAF-BAL1117-120SN | AAF-BAL 11/17 110 – 120V single phase |

| AAF-BAL1117-208SN | AAF-BAL 11/17 200 – 210V single phase |

| AAF-BAL1117-208TX | AAF-BAL 11/17 200 – 210V three phase |

| AAF-BAL1117-230SN | AAF-BAL 11/17 220 – 240V single phase |

| AAF-BAL1117-230TX | AAF-BAL 11/17 220 – 240V three phase |

| AAF-BAL1117-400TN | AAF-BAL 11/17 380 – 415V three phase |

| Temperature controller options | |

| &02-301 | 301 single ramp PID controller |

| &02-3216CC | 3216CC PID controller |

| &02-301-3016 | Upgrade from 301 to EPC3016P1 1x 24 segment programmer |

| &02-301-CT1-1Z | Upgrade from 301 to CC-T1 touchscreen temperature programmer for single-zone products |

| &02-301-3008P10 | Upgrade from 301 to EPC3008P10 10x 24 segment programmer |

| &02-NanoPR | Upgrade to Nanodac PR |

| Built-in features and options – control options | |

| TMP-DIGOT-F | Digital over-temperature protection |

| &06-CS | Cascade control: chamber furnaces up to 1200°C (includes flexible type N thermocouple in the chamber) |

| &08-232 | RS232 Communications |

| &08-485 | RS485 Communications |

| TMP-CALIB-CF11 | Single temperature, single position factory calibration of workspace for chamber furnaces, using equipment traceable to national standards. Please specify temperature (up to 1100°C maximum) and position when ordering. |

| TMP-CALIB-CF15 | Single temperature, single position factory calibration of workspace for chamber furnaces, using equipment traceable to national standards. Please specify temperature (up to 1550°C maximum) and position when ordering. The price includes the installation of a 12mm ID thermocouple access port. |

| &08-06-01 | Temperature alarm relay connection (please specify alarm temperature) |

| &08-06-02 | Program segment output |

| &08-06-04 | Audible alarm with separate cancel button |

| &08-06-05 | Audible alarm on over temperature with separate cancel button |

| &14-K-132 | Built-in digital temperature indicator (132 series) for Type K thermocouples |

| &14-N-132 | Built-in digital temperature indicator (132 series) for Type N thermocouples |

| &08-TYPE-X | Panel-mounted thermocouple socket for connection to spare Nanodac recording channel (please specify thermocouple type: X = K, N, R, B, 2) |

| &08-BAL-AV1 | Advanced version for EPC3008P10: balance is linked to temperature controller for logging of temperature & weight loss |

| &08-BAL-AV2 | Advanced version for Nanodac: balance is linked to temperature controller for logging of temperature & weight loss |

| Built-in features and options – voltage options | |

| TMP-2PH-AAF | 2 phase |

| Built-in features and options – gas options | |

| &11-33 | Inert gas inlet for chamber furnaces and ovens |

| 41-30-21 | 100mm Flowmeter for chamber furnaces or ovens with gas inlets or retorts (Ar2-22 l/min) |

| 41-30-22 | 100mm Flowmeter for chamber furnaces or ovens with gas inlets or retorts (CO2 2-20 l/min) |

| 41-30-24 | 100mm Flowmeter for chamber furnaces or ovens with gas inlets or retorts (N2 2-25 l/min) |

| 41-31-1-50 | Solenoid valve with manual switch for 50 Hz power supply |

| 41-31-1-60 | Solenoid valve with manual switch for 60 Hz power supply |

| 41-31-2-50 | Solenoid valve with automatic switch for 50 Hz power supply |

| 41-31-2-60 | Solenoid valve with automatic switch for 60 Hz power supply |

| Built-in features and options – build options | |

| &11-18-01 | Unglazed viewport |

| &11-18-02 | Glazed viewport |

| &11-28-01 | Sheathed thermocouple calibration port (up to 1300°C) |

| &11-28-04 | Unsheathed thermocouple calibration port through the back wall of the chamber (12mm diameter – please state required position when ordering) |

| &11-28-05 | Unsheathed thermocouple calibration port through the centre of chamber roof (12mm diameter) |

| &11-28-06 | Unsheathed thermocouple calibration port through the centre of door (12mm diameter) |

| Optional Accessories | |

| 00125-3-1007 | Tray handle for AAF trays or VMF 10/6 crucible stand |

| 40-209-460-0050 | Fused silica crucible |